Reduce risk from every build

We know you need to minimise risk at every step of the build process because it’s what keeps your customers up at night.

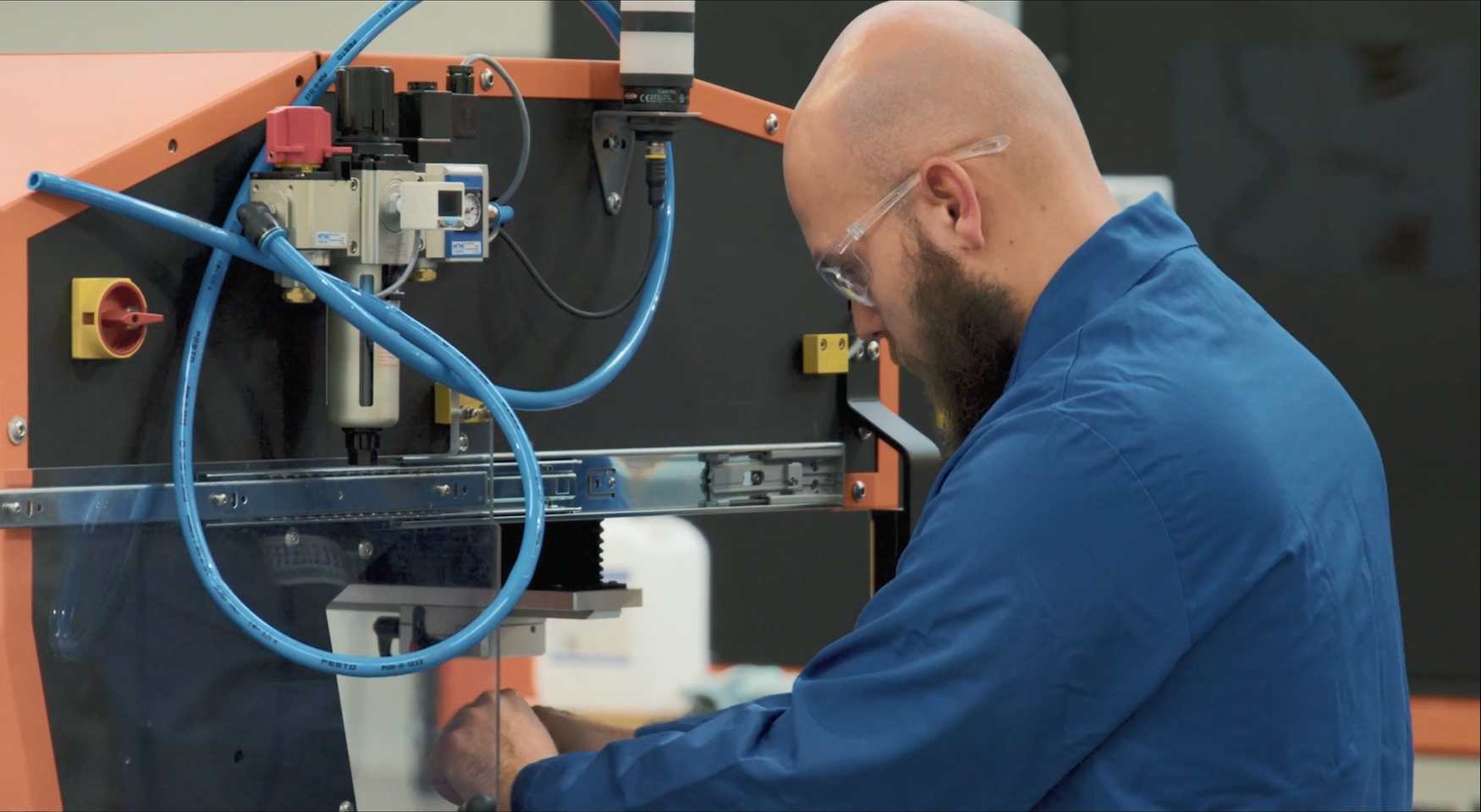

Mitsubishi Electric robots help drive quality control in high-speed inhaler testing line

Software solutions lineup

Product lineup

Services

Meeting targets

Meeting regulatory standards

Whitepaper - Genesis64 FDA 21CFR11 Capabilities

Whitepaper Download Form

Download Whitepapers

Improving reliability

Whitepaper - Intelligent Control Systems

Whitepaper Download Form

Download Whitepapers

Managing digital threats

Whitepaper - Comprehensive Guide to Safeguarding Operational Technology

Whitepaper Download Form

Download Whitepapers

Machine building strategies and solutions

Contact us for more information

Competencies

Our Stories

![HAMBI Steel Mesh [Img 1]](https://eu-images.contentstack.com/v3/assets/blt5412ff9af9aef77f/blt9d766b0fc1b7a486/67bf27a084fd866c89de3c96/Hambi_maschinenbau.jpg?auto=webp&quality=100&format=jpg&disable=upscale)

2025-01-09

NEWThe world's first fully automated line for reinforcing steel mesh

Hambi Terhoeven GmbH & Co KG

Watch the video on YouTube

#Machine Building#Material Handling#Visualization#Programmable Controllers MELSEC#Servo motors

![[Thumbnail] Innovation in dairy production](https://eu-images.contentstack.com/v3/assets/blt5412ff9af9aef77f/bltfae4cdd88be35f7a/675823ae19771e6809a85679/Innovation_in_dairy_production.png?auto=webp&quality=100&format=jpg&disable=upscale)

2024-10-07

NEWInnovation in dairy production

Advanced Machine Company AS (AMC) x Tine SA

Watch the video on YouTube

#Machine Building#Food & Beverage

2024-08-01

NEWFrom food waste to soil in 24 hours

Solserv AB

Watch the video on YouTube

#Food & Beverage#Machine Building#Sustainability#Energy#Visualization#Inverters-FREQROL#Controllers

2024-04-19

NEWIndustrial Printing Solutions

KELLER

Watch the video on YouTube

#Machine Building#Life Science

.jpg?auto=webp&quality=100&format=jpg&disable=upscale)

2023-10-10

Printing Success: Futureproof and cost-effective solution

JK Machinery

#Machine Building#AC Servos-MELSERVO

![[Thumbnail] Quality Control in High Speed Inhaler Testing](https://eu-images.contentstack.com/v3/assets/blt5412ff9af9aef77f/bltec0b49d0ea7e4e73/673211f255ee8a3647f032bc/QualityControl_inhaler.jpg?auto=webp&quality=100&format=jpg&disable=upscale)

2020-03-06

Quality Control in High Speed Inhaler Testing

Pharma Industry

Watch the video on YouTube

#Life Science#Machine Building#Controllers#Robots

2019-07-06

Robot duo cuts cakes & much more

Western Mechanical Handling (WMH)

Download PDF

DE#Food & Beverage#Machine Building#AC Servos-MELSERVO#Human-Machine Interfaces (HMIs) - GOT#Industrial Robots - MELFA#Controllers

2018-06-06

Thermoforming machine saves up to 95% space in the cleanroom

Riverside Medical Packaging

Download PDF

DE#Life Science#Packaging#Machine Building#Controllers#Human-Machine Interfaces (HMIs) - GOT